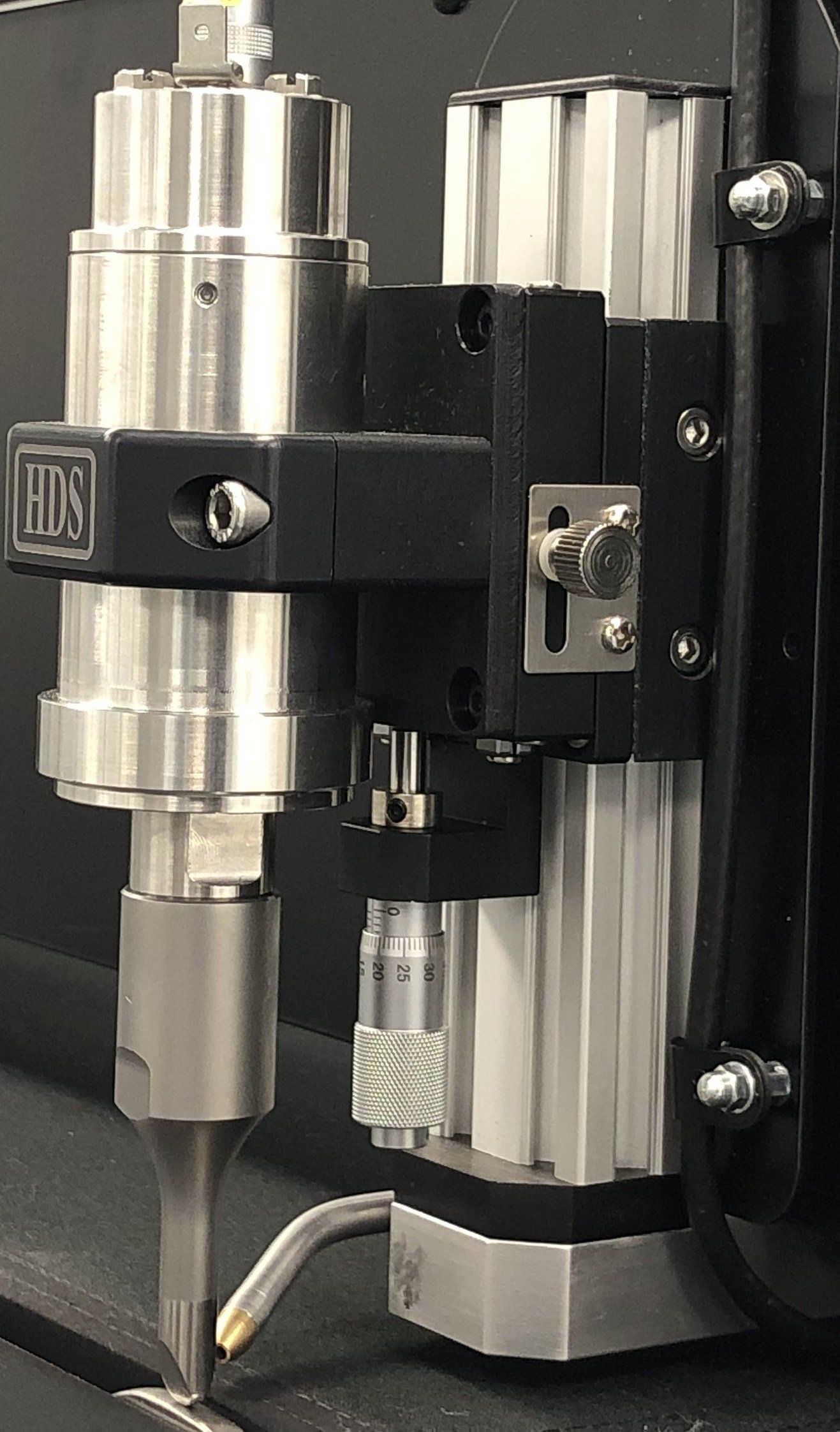

Micro Head Adjustment

Used for the precise setting of the probe tip height depending on the film thickness.

Malti

mt

Malti

mt

íslenska

is

íslenska

is

Монгол

mn

Монгол

mn

Ελληνικά

el

Ελληνικά

el

Bahasa Melayu

ms

Bahasa Melayu

ms

Suomi

fi

Suomi

fi

shqip

sq

shqip

sq

עברית

he

עברית

he

slovenščina

sl

slovenščina

sl

Español

es

Español

es

हिन्दी

hi

हिन्दी

hi

magyar

hu

magyar

hu

Français

fr

Français

fr

հայերեն

hy

հայերեն

hy

ქართული

ka

ქართული

ka

Français

fr

Français

fr

português

pt

português

pt

Deutsch

de

Deutsch

de

polski

pl

polski

pl

bosanski

bs

bosanski

bs

русский

ru

русский

ru

slovenčina

sk

slovenčina

sk

ਪੰਜਾਬੀ

pa

ਪੰਜਾਬੀ

pa

eesti

et

eesti

et

Беларуская

be

Беларуская

be

română

ro

română

ro

한국어

ko

한국어

ko

Bahasa Indonesia

id

Bahasa Indonesia

id

Italiano

it

Italiano

it

繁體中文

zh-tw

繁體中文

zh-tw

български

bg

български

bg

Latviešu

lv

Latviešu

lv

Србија

sr

Србија

sr

hrvatski

hr

hrvatski

hr

简体中文

zh

简体中文

zh

日本語

ja

日本語

ja

čeština

cs

čeština

cs

Euskera

eu

Euskera

eu

English

en

English

en

català

ca

català

ca

lietuvių

lt

lietuvių

lt

português

pt

português

pt

Dansk

da

Dansk

da

العربية

ar

العربية

ar

norsk

nb

norsk

nb

HDS have been sucessfully manufacturing and supplying this range of ultrasonic document encapsulators to institutes world-wide since 1992.

Our focus has alway been on quality and reliability.

Featured on all machines

| Specifications: | Keeper 900 | Keeper 1300 |

|---|---|---|

| Supply Voltage | 230 VAC or 110 VAC | 230 VAC or 110 VAC |

| Dimensions | 1260 x 840 x 450 mm | 1660 x 960 x 450 mm |

| Weld Length | 890 mm | 1290 mm |

| Weight | Approximately 50 Kg | Approximately 60Kg |

Micro Head Adjustment

Used for the precise setting of the probe tip height depending on the film thickness.

Probe height Lock

Keeps a fixed height setting during the welding process.

Recommended to be used on thicker films, or for when welding film to thin card.

Probe Tip Cooling

Maintains a steady stream of cold air to stabilize the heat build up transmitted from the weld.

This is important to establish a consistent and repeatable weld, especially for long welds.

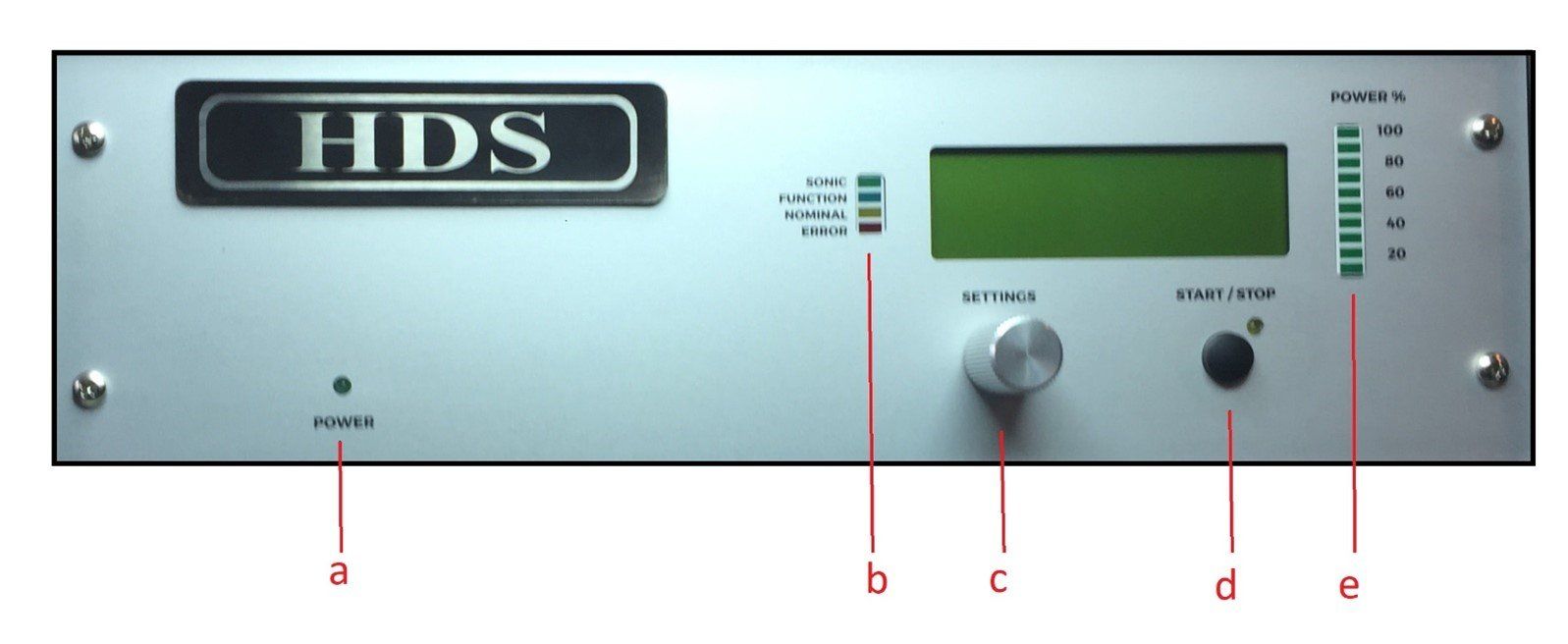

Ultrasonic Generator:

a) Power on indicator.

b) Function Indicator.

c) Function Selector. Used to set Amplitude (50-100%)

d) Test Button.

e) Power Output Display.

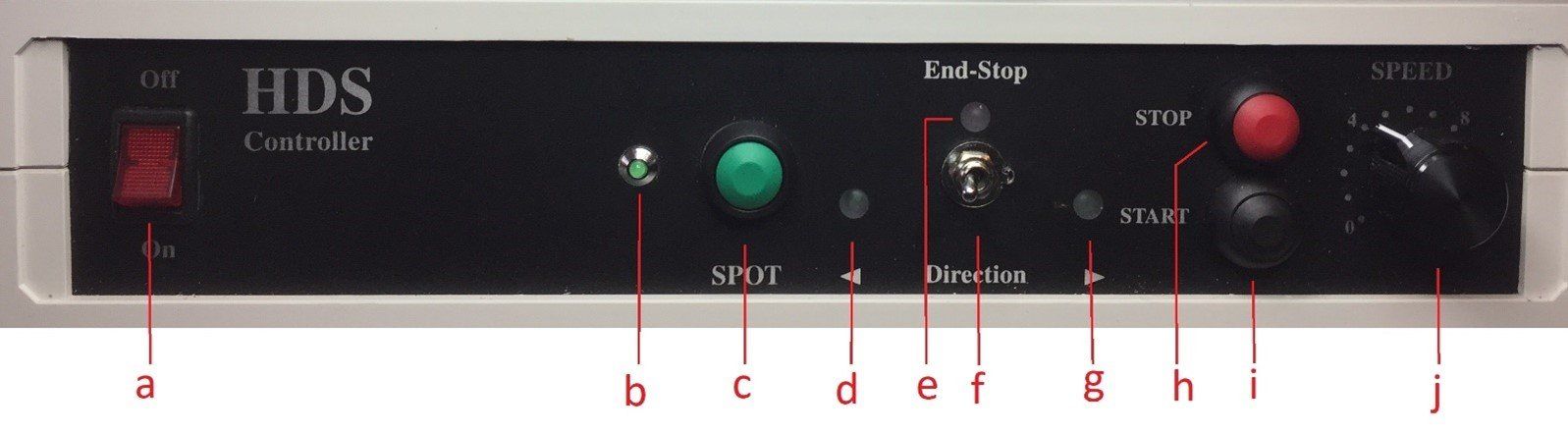

Speed Controller

Ultra long life precision linear drive unit

| 1 | Toothed belt drive | 9 | Grease nipple |

|---|---|---|---|

| 2 | Toothed belt | 10 | Guidance slides |

| 3 | Guidance section | 11 | Adapter plate |

| 4 | Guidance shaft with support section | 12 | Toothed belt steering |

| 5 | Toothed belt tensioning kit | 13 | Cover |

| 6 | Roller cover | 14 | Felt wiper |

| 7 | Guidance shaft lubrication | ||

| 8 | Roller |

Registered Address:

Severn House,

Hazel Drive,

Newport

Wales

NP10 8FY

UK